1. The principle of effective binding and reinforcement between goods and boxes is to prevent the goods from overturning to both sides of the container or sliding to both ends (Rack) during lifting and navigation of special containers, thus causing damage to the goods;

2. It is forbidden to erect one end of the rack and lay down the other end of the rack. The racks at both ends must be erected or laid down at the same time;

3. The goods shall be evenly arranged on the floor of the special container according to the weight, and shall not be biased towards one end. The goods shall be prevented from overturning to both sides and longitudinal sliding by binding and wooden wedges. For large goods with a high center of gravity, the center of gravity shall be lowered;

4. Crosstie shall be padded between the goods and the floor of the special container to increase the friction coefficient, and supports shall be filled between the goods and the racks at both ends of the Flat Racks to prevent longitudinal movement;

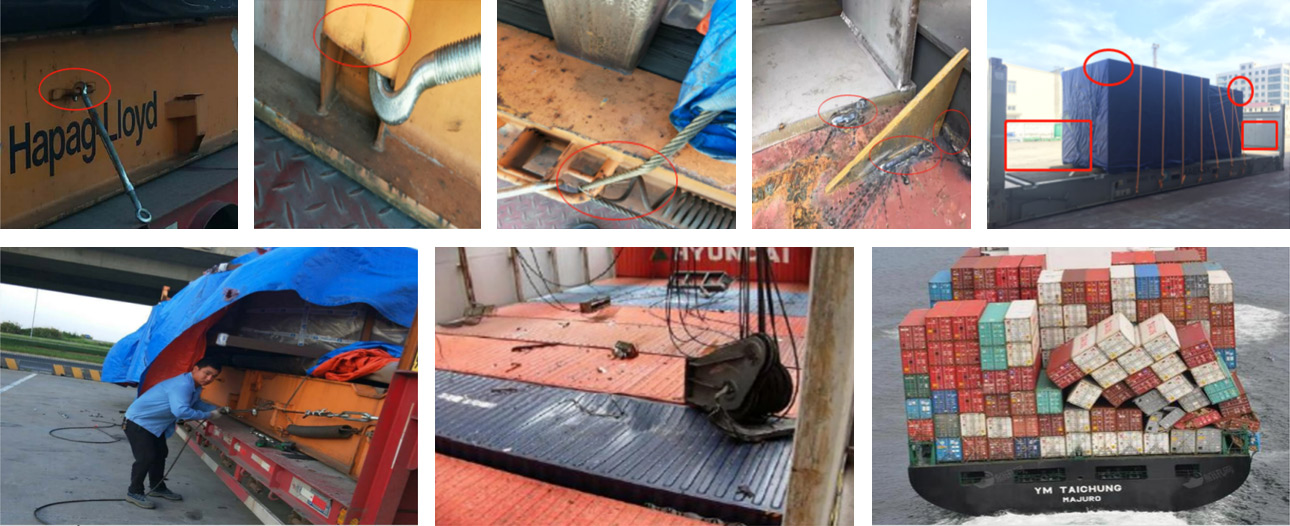

5. It is forbidden for goods and reinforcement tools to cover the four corner Casting of the Flat Rack, namely the lifting points; A clearance of at least 35cm shall be reserved between the cargo and the outer edge of the rack of the Flat Rack. Otherwise the Flat Rack will unable to go down the cabin;

6. The load of each reinforcement point on both sides of the Flat Rack is usually 5 tons, and it should be avoided that the binding is concentrated on a reinforcement point;

7. It is prohibited to nail crosstie or wooden wedges into the wooden floor of the Flat Rack with iron nails to avoid damage to the Flat Rack and reduce its bearing strength;

8. The steel wire rope or nylon binding belt used for binding must be kept fully tensioned, the steel wire rope must be equipped with turnbuckles, and the nylon binding belt must be equipped with anti reverse ratchet fasteners or eye buckles;

9. The contact point between the steel wire rope or nylon binding tape used for binding and the edge of the goods shall be padded, and the cushion layer shall be made of plastic materials (paper boxes are prohibited); The contact point between the shaft and coil steel perforated wire rope and the cargo edge shall be covered with plastic rubber tube pad;

10. For the platform container, after the racks at both ends of the Flat Racks are put down, the width of the cargo passing through the lifting points should be controlled within 2.08m, otherwise the cargo will cover the lifting points, which will cause the wharf machinery unable to lift.

Risks caused by unqualified reinforcement: refusal to enter the port, refusal to ship, cargo damage, box damage and personal injury